Dental Lab Software

Powered by advanced AI technology, Oqton’s dental lab software automates digital production workflows for all dental applications.

Boost your efficiency and start saving valuable time and money with Oqton Manufacturing OS today.

Our clients in the spotlight

“Oqton is a gamechanger – it already helped increasing our productivity by 30%. We fit more parts per build, while still reducing print times. And we significantly reduced data preparation.”

- Eric Fortin, VP Production

“Oqton consistently maintains the highest level of quality that has enabled us to increase efficiency and scalability exponentially.”

- Andy Timblin, CAD/CAM Production Supervisor

“Since we started using Oqton, we have reduced the data preparation time our technicians need to set up the machines by 65%, which has meant an extraordinary improvement in terms of time and quality”

- Juan Carlos, Production Director

faster data preparation from intelligent automation

productivity

with denser nesting, faster printing or easier support removal

ready

for any scale, from small lab to large production center

Why Oqton for Dental Production?

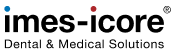

Oqton provides automated dental workflows to help you meet growing production goals while significantly reducing manpower requirements. An end-to-end, integrated dental production system, Oqton ensures full traceability to future-proof your business.

Our platform is agnostic, replacing multiple disconnected software applications, across all of your machines.

Applications

- Metal 3D Printing

- Aligner Production

- CNC Milling

- Production Management

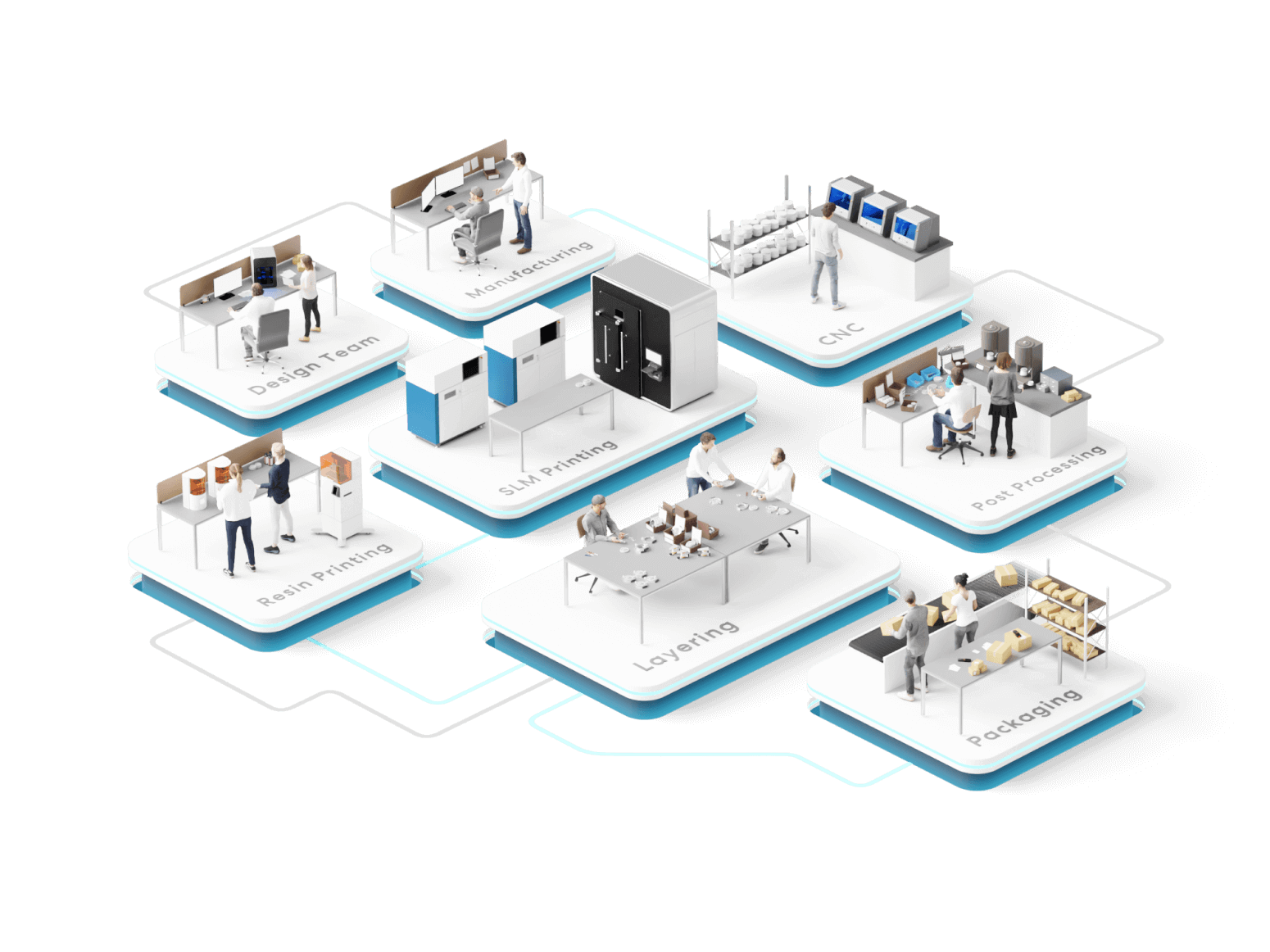

Metal 3D Printing

Maximize Productivity of Complex Technology

Smart automation saves up to 90% in data preparation time

Layered nesting of crowns & bridges, and high-density, interlocked nesting of RPDs

Optimized supports for easier support removal and reduced finishing

Aligner Production

Connect and Automate your production

Connecting design, 3D printing, thermoforming, laser marking, CNC trimming, labelling and packaging

Fully automated data preparation and optimized nesting for cost-effective production

Easily scalable, across multiple location, and ready for any volume

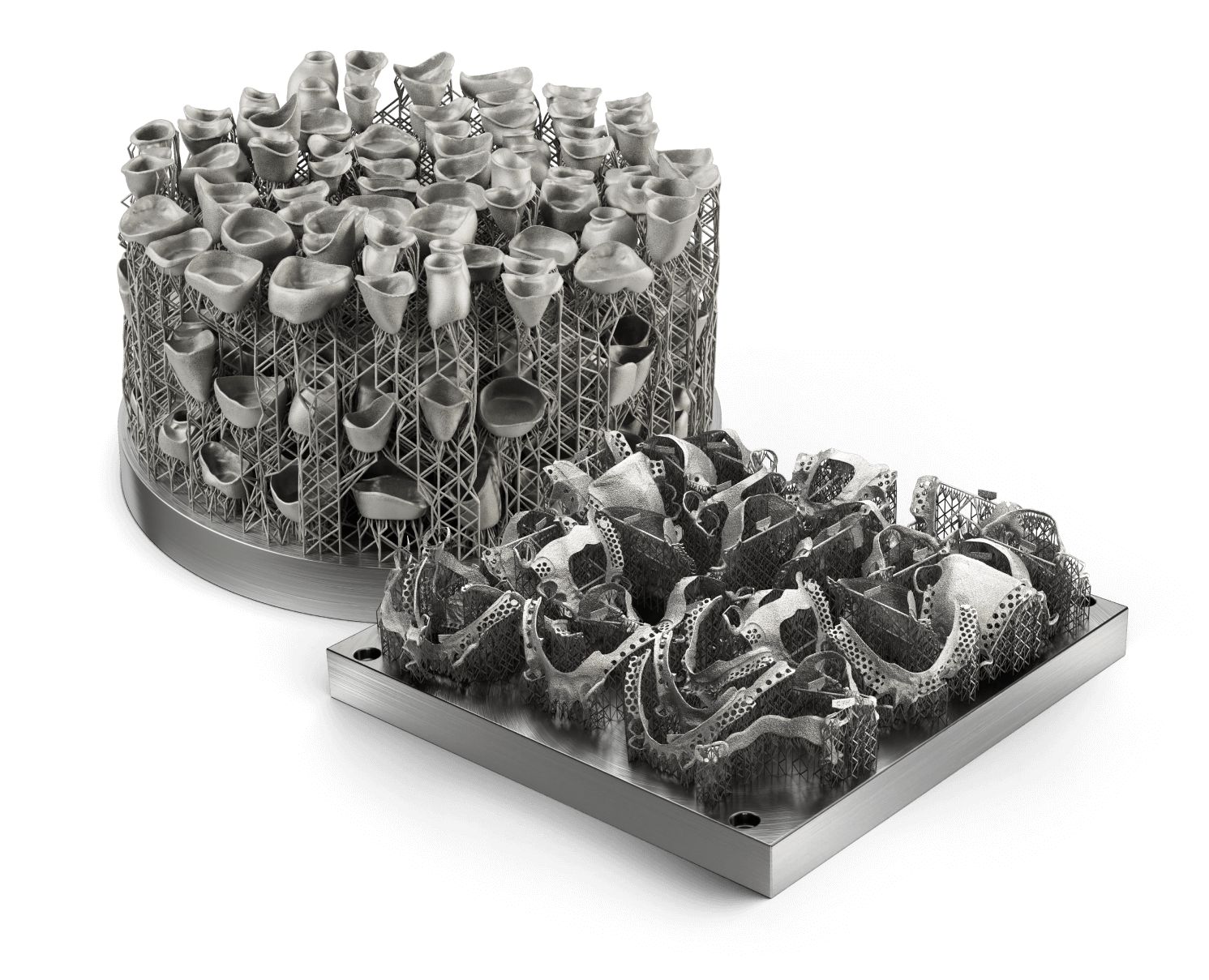

CNC Milling

Avoid Repetitive Tasks

AI-driven automation of CAM workflows, including automatic stock selection, nesting, and toolpath generation

Machine learning capabilities for orientation and pin placement

Optimised machining efficiency and consistent results based on feature detection and automated assignment of milling templates.

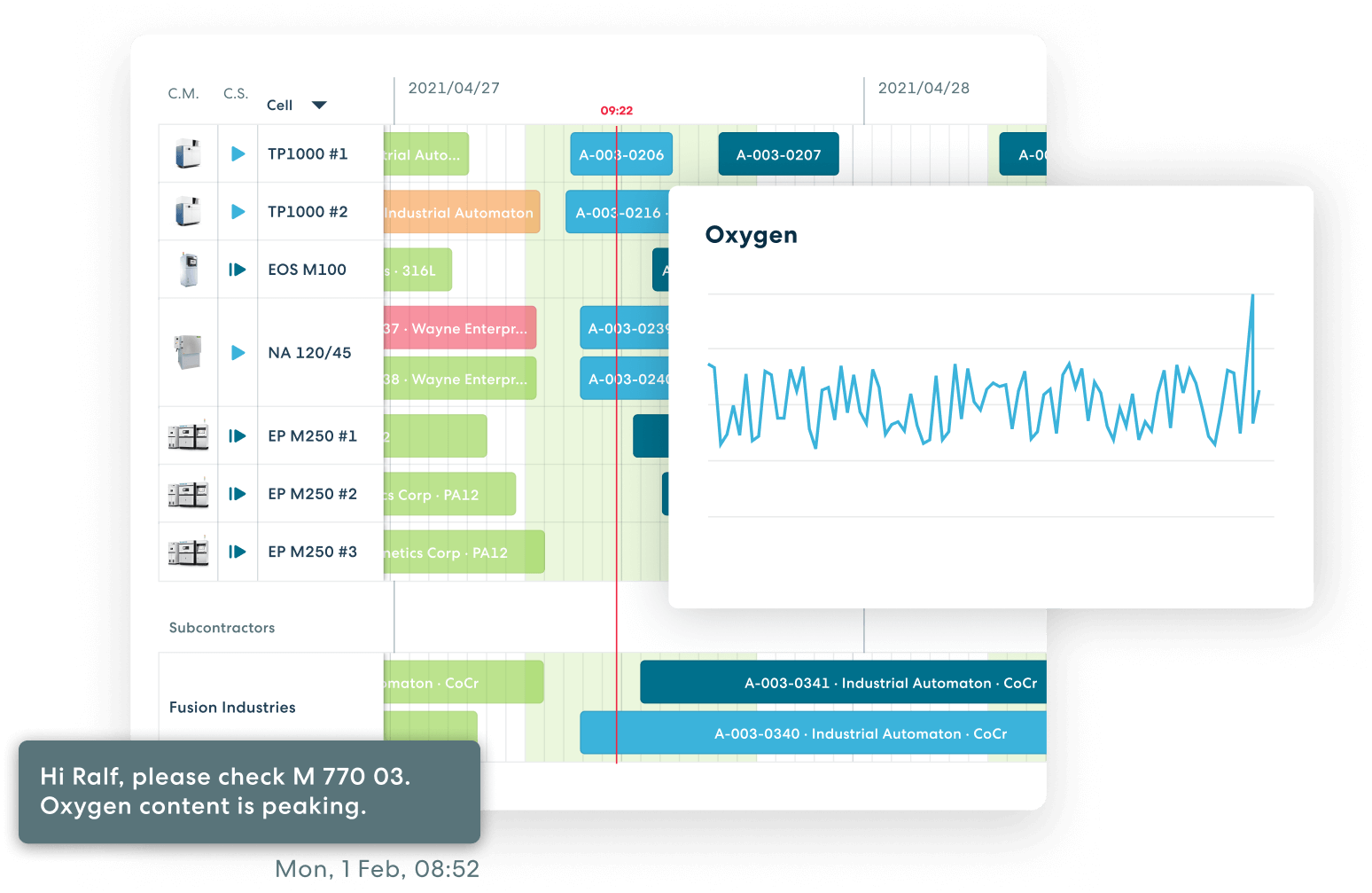

Production Management

Schedule, Track and Trace your entire production

Prepare, plan, schedule, track and trace your entire production facilities

End-to-end traceability of materials, tools, parts and jobs with full revision history

Rich data can be gathered automatically by integrating and connecting CAM, MES and IoT

"Insane" cost and productivity improvements

Customer story - Crown Ceram

Production efficiency with peace of mind?

Connect with us for a personalised demo!

Trusted by industry partners